CUHK

News Centre

CUHK Showcases Novel Technologies at the International ICT ExpoRoll to Roll Microcontact Printing for Manufacturing Low-cost Photonic Devices

The Chinese University of Hong Kong (CUHK) will showcase over ten technological research projects at the coming International ICT Expo 2014 at the Hong Kong Convention and Exhibition Centre from 13 to 16 April. One of the featured projects is the ‘Precision Roll to Roll Microcontact Printing’ technology which is developed for cost-effective and high-throughout fabrication of flexible photonic devices.

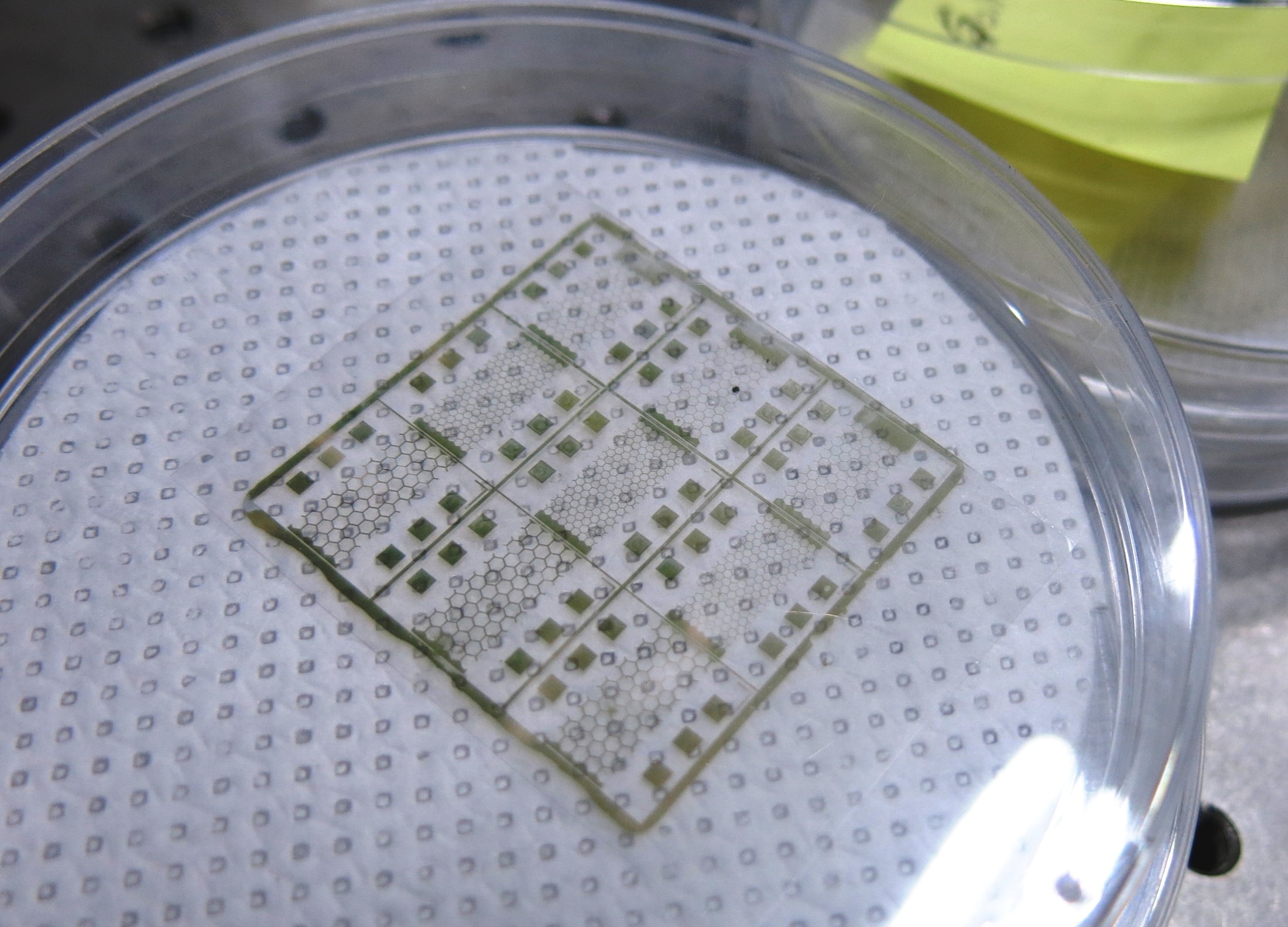

Optical gratings and transparent electrodes, which are produced with submicron technology, are essential components in a wide range of optoelectronics devices, such as LCD displays, touch screens, organic LEDs, organic photovoltaic cells, as well as biomedical devices, laboratory spectroscopy systems, lasers etc. The conventional approach for fabricating submicron resolution patterns is photolithography or electron-beam lithography, which can create extremely precise patterns (50 nanometers). However, these processes are expensive, complex and need to be performed in a cleanroom. Taking fabrication of transparent gold microelectrodes as an example (a device commonly used in optical instruments like organic photovoltaic cells), the process has to be carried out in a cleanroom environment using standard lithography and lift-off techniques. The production takes approximately 15 steps and at least half a day and yet, only small pieces can be produced.

To solve this problem, researchers have developed the Microcontact Printing (MCP) technique in the hope of replacing the conventional production processes. It is a soft lithography technique which can overcome the diffraction limit and operate in a non-cleanroom environment. However, MCP still has a lot to overcome for large scale manufacturing, including speed, accuracy, stability, and control of printing force.

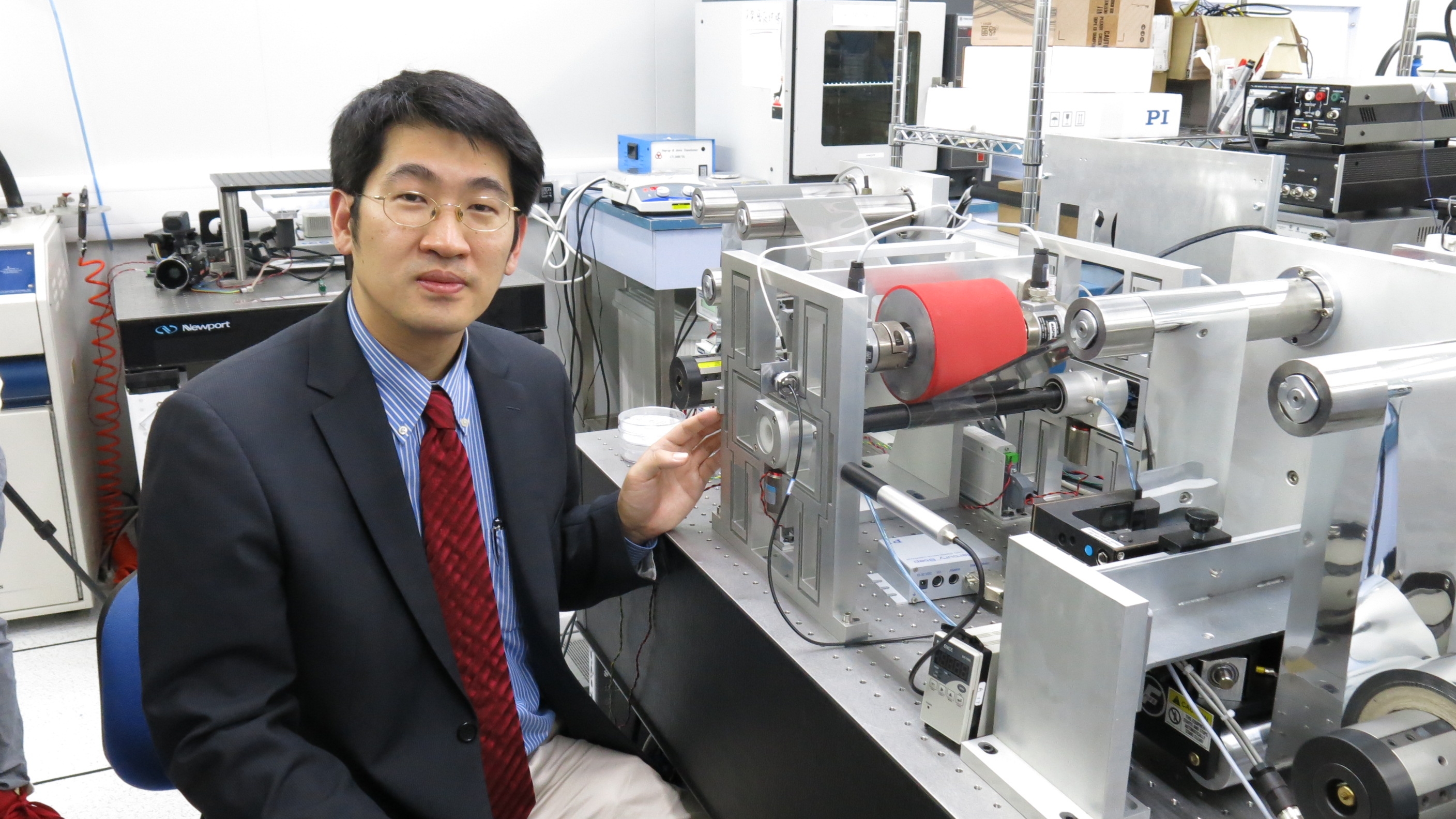

Prof. CHEN Shih-Chi, Department of Mechanical and Automation Engineering, CUHK, and his team have recently developed and constructed a flexure-based precision roll-to-roll (R2R) printing system that demonstrates multi-axis submicron level precision and repeatability. Several R2R compatible molecular ink formulations for different metals have also been developed. The technology can substantially improve printing speed, resolution and repeatability. Experiments indicated that the R2R system can control the printing force within ±0.05N and the system position within ±0.5µm. And the highest resolution can reach 100 nm. Using the same example as above, the technology enables fabrication of transparent gold microelectrodes to be performed in a non-cleanroom environment. The system rollers roll continuously just like printing paper, and large area transparent gold microelectrodes can be produced within a minute.

The developed technology could be widely applied to mass manufacture cost-effective flexible photonic devices and it is ready to commercialize for production. In the future, foldable electronic devices like tablets and LCD displays can be produced in low cost, and become our common daily accessories.

To know more about the aforementioned technology and other recent technological projects, please visit the booth of CUHK at the International ICT Expo (Booth No.: 3G-B04).

Prof. CHEN Shih-Chi, Department of Mechanical and Automation Engineering, CUHK and his precision roll-to-roll microcontact printing system.